Instruction

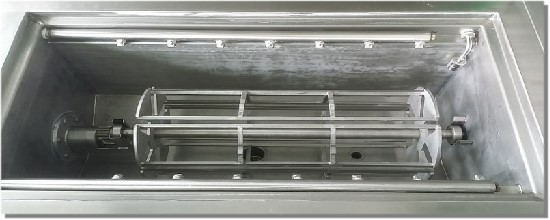

Full-automatic Squeegee Cleaning Machine. Through using ultrasonic, agitating, spraying and other cleaning methods to thoroughly clean the squeegee, and give customers a clean, clean printing environment.

Equipment Feature

1. Change the traditional way of wiping squeegee by hand online to avoid contamination of tin paste.

2. Replace manual cleaning, avoid direct contact between hands and solvents, reduce the harm to human body .

3. Effective recovery of residual solder paste, reduce solder paste waste in the production process.

4. The cleaning effect reaches 99.9%, reducing the risk of steel mesh blockage.

5. Keep the squeegee clean, ensure good printing quality, prolong the service life of the squeegee.

Equipment Parameter

| Model No. | ASM-600-Ⅱ |

| Suitable model | All |

| Suitable squeegee | L<580mm H<80mm |

| Cleaning amount | 6 Set |

| Cleaning speed | 5Min/1 Set |

| Control | Touch screen + PLC |

| Cleaning fluid | Water–based cleaning fluid |

| Filter | First level filter core + Second level solder paste recovery |

| Power supply | 380V |

| Power | 7KW |

| Size | 1300×900×1235mm(L×W×H) |

| Weight | 330Kg |

Advantage:

1.The operation is simple, intuitive and convenient.

2.Cleaning squeegee quantity, short time.

3.360 degrees without dead Angle rotating cleaning.

4.Filter the paste and recycle it.

5.Automatic hot air drying.

6.Automatic hot air drying.