Double Buckets (5L X 2) Centrifugal Type PCB Printing Ink Mix Machine

- Model NO. SBT-TP5000S

Non Vacuum Centrifugal Type No Contact Mixing

- The Material can be mixed Fluorescent powder,silicone gel, silver paste, aluminum paste, adhesives, ink, silver nanoparticles, silver nanowires, LED/OLED/SMD/COB conductive silver paste, insulating adhesive, RFID printed conductive ink , Anisotropic conductive adhesive ACP, conductive paste for thin-film solar cells, conductive ink for PCB/FPC, cosmetics, etc.

Product Description

Types: SBT-TP5000S is a planetary centrifugal mixer, mainly applied in Electronic printing ink or PCB printing ink for reach material homogeneous effect.

Introduction

1.Rotation/Revolution while working with high power vacuum pump,equipment can stir the material evenly in few seconds or few minutes,stir and vacuum complete at the same time.

2.Mixing capacity varies from a few grams up to 10000 grams by using different containers, meet the requirement from laboratory use to volume production.

3.Up to 5 preset programs(Can be customized), every program can be divided to 5 segment, each segment with different mixing time and speed, able to deal with different types of the materials.

4.Max rotation speed is 1500rpm, high viscosity material can be mixed evenly .

5.The equipment is suitable for customer who have high volume demand. Single cup can mix up to 5000g, double cup can mix up to 10000g.

6.The key parts are all from industrial famous brands from home and abroad, to guarantee the stability of equipment under long time and high load operation.

Tips:

No further notice if there is appearance and specification change.

The product is non-explosive proof ,do not stir danger or hazardous material

Application Area:

LED Sealing&Package

Adhesive

Silicone Rubber

Cathode&Anode Material for Li-ion Batteries

Polymer Material

Silver Paste

Epoxy Resin

Pharmaceutical

Ink

Conductive Paste

LCD

Laboratory

Characteristic:

1.Max mixing capacity 5000g each cup.

2.The equipment stir the material under vacuum status through high-speed revolution/rotation (max 1500RPM) to achieve deaeration effect.

3.The equipment is non-contact stirring.

4.High viscosity resin can be stirred and achieve ideal deaeration effect in short time ,and material no overflow.

5.High stability performance.

Mixing effect:

Applied Mixing Samples for various kinds of chemical material cases:

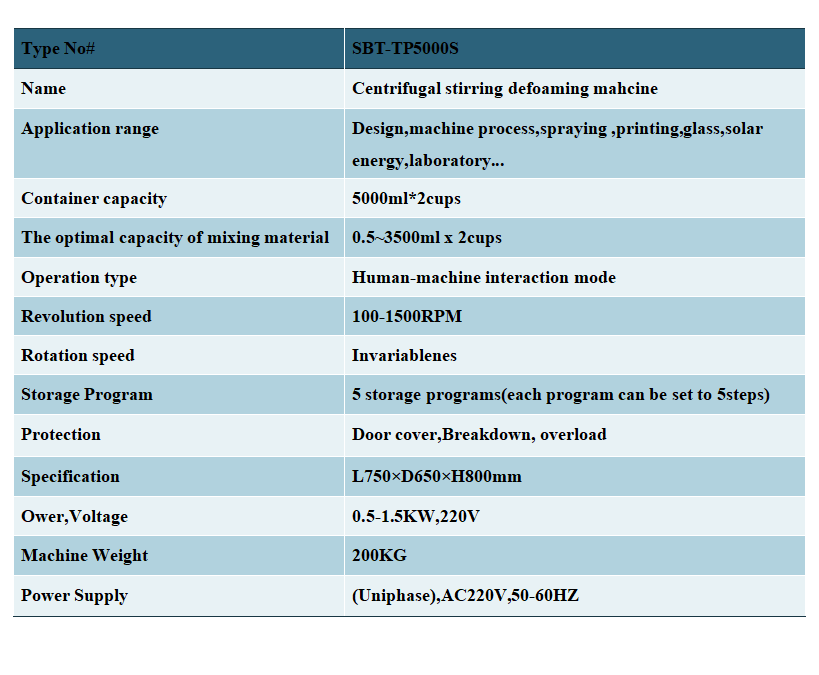

-Technical Parameter