Equipment Application Introduction

The semi-automatic stencil inspection machine is a device that performs high-precision inspection on the cleaned stencils after printing. It is mainly used to control the quality of stencils after cleaning, optimize the process research and measurement of stencil openings, and at the same time automatically record and upload the results of the process of stencil use-cleaning-cleaning detection-use storage-scrap and achieves automated management of the information chain;

The equipment makes up for the shortcomings of low manual inspection efficiency, poor quality, inability to perform data management and traceability, and inability to improve the process. It provides a crucial reference for the improvement and quality control of the printing process.

Equipment Design principle:

Use image automatic measurement technology to collect parameters such as the opening size, opening position, and number of openings of the standard stencil, and then compare it with the cleaned stencil to determine whether it is qualified within the set error range.

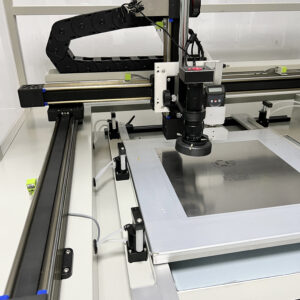

System composition:

ITEMS | SPECIFICATION |

Main part | marble platform + cast body gantry structure; |

Control part | motion control panel + control computer; |

Driving part | motor driver; |

Moving parts | motor, belt, guide rail, slider; |

Feedback part | photoelectric switch, sensor, signal transfer, high-precision grating ruler; |

Optical part | camera, lens, light source, light source control; |

Function Features:

TYPE | FUNCTION ITEM | FUNCTION SPECIFICATION |

Inspection Function |

Stencil aperture Test | Aperture position,size,quantity,foreign body,tension,glitch, hold blocking,multi hole,miss hole. |

Automatic Tension Test | High acc tension meter,five points position test; Precision: ±1N/cm; tension range:0~50N | |

Software function | Stencil information management system | Stencil information management |

Stencil bar code scan information management | Quickly manage stencil programs through bar code scanning. | |

MES system data interchange upload | MES information upload and management functions. |

Equipment Parameter

SN | Type | Item | Description |

1 | Brand | Brand Name | SUBIT |

2 |

Specification | Model No. | SBT-JC1009SA |

3 | Inspection Application | Stencil cleaning effect,foreign body inspection,tension test. | |

4 | Inspection Items | Aperture position,size,quantity,foreign body,tension,glitch, hold blocking,multi hole,miss hole. | |

5 | Inspection Speed | 0.8 sec/FOV | |

6 |

Inspection Accuracy | Size Measure accuracy | The Highest 3.45μm (same FOV inner resolution:0.345um) |

7 | Area Measure accuracy | Gr&r<5% | |

8 | Position Accuracy | Repeatability 3~8%,grating scale accuracy±1μm | |

9 | Tension test | High accuracy Tension meter,multi position test freely; accuracy: ±1N/cm,tension range:0~50N | |

10 | Min. Inspection component | 80μm * 80μm | |

11 |

Optics System | Camera | 20millon |

12 | Lens | Customized Telecentric Optics lens | |

13 | Top Light | Toriodal LED top light | |

14 | Bottom Light | White LED light source | |

15 | FOV | 14.1*10.3mm | |

16 |

Stencil spec. | Stencil frame | Support 850*850*60mm below |

17 | Max.detection range | 650*650mm | |

18 |

Equipment Spec. | Appearance(L*W*H) | 1650*1400*1750mm |

19 | Weight | 1000KG | |

20 | Equipment frame | Stainless steel weld with painting | |

21 | Drive system | Servo motor+motion control card |