-Main Application Field

Light-emitting diode (LED), touch screen (TP), medical equipment, electronic components, nano-powder materials, fine chemical materials, printed electronic materials, electronic packaging materials and new energy materials such as high, sharp, precision products Mixing and stirring of materials,

The Material can be mixed: fluorescent powder,silicone gel, silver paste, aluminum paste, adhesives, ink, silver nanoparticles, silver nanowires, LED/OLED/SMD/COB conductive silver paste, insulating adhesive, RFID printed conductive ink , Anisotropic conductive adhesive ACP, conductive paste for thin-film solar cells, conductive ink for PCB/FPC, cosmetics, etc.

-Equipment Features

- Apply to various kinds of brands liquid stuff such as ink, paste,solder cream,liquid stock and so on, it can be mixed and stirred two jars at the same time, centrifuge stir in vacuum environment, which can save more time and improve the work efficiency.

- Unique appearance, good-looking, practical, advanced painting technical.

- Mixing theory: motor revolution and rotation method, no need ice away after the freeze cream solder taking out.

- Material can be returned temperature in short time and stir evenly then for normal use.

- High automatically,stable performance, easy operation, high safe standard, maintain easily and fast.

- Jar cap no need open while in mixing and stirring process,otherwise the material would absorb air or to be oxidized.

- With enclosed sealing environment, operation time can be fixed, that ensure cream flexible stability and new/old cream mixing completely.

- Revolutionspeed can be controlled, 0-2200 turns /min. Rotation speed is invariablenes.

-Details

Key Components Description

Spindle: Made of ASSAB S136 mirror die steel, after multiple heat treatments, the overall hardness reaches HRC62 degrees. The shaft is ground as a whole,The sealing surface is mirror-polished to achieve a mirror-like effect with a surface roughness of 0.02um,achieving high sealing performance with a long life.

Sealing ring: It adopts the super wear-resistant sealing ring of Bayer Company of Germany, and the wear resistance capacity can reach the line speed of 40M/S. The line speed of our equipment is only 4M/S at 2000 rpm. The pressure can withstand 20KG/c ㎡.

Vacuum pump:German technology Small Diamon vacuum pump, built-in forced lubricating oil pump, sufficient lubrication, reliable performance, low noise, with our company’s unique 4-stage filtration, to meet the requirements of clean room.

Gear:It adopts the structure of automobile spiral bevel gear, and the material is upgraded to super wear-resistant nylon, which has stable operation, low noise and long service life.

Electrical accessories: Toshiba inverter, NSK bearing, Omron PLC, SMC vacuum gauge solenoid valve, Izumi Electric relay, Aifaco vacuum pump, Samkoon touch screen, high-quality electrical accessories ensure durability and stability.

Swivel arm: It adopts the whole swivel arm, which is all made of magnesium-aluminum 7075 imported from the United States, which ensures the accuracy and later stability of the product, and the center error is not greater than ±0.02. High interchangeability, the same type of machine arm can be interchanged freely, easy maintenance. The transmission mechanism has a long service life and is maintenance-free.

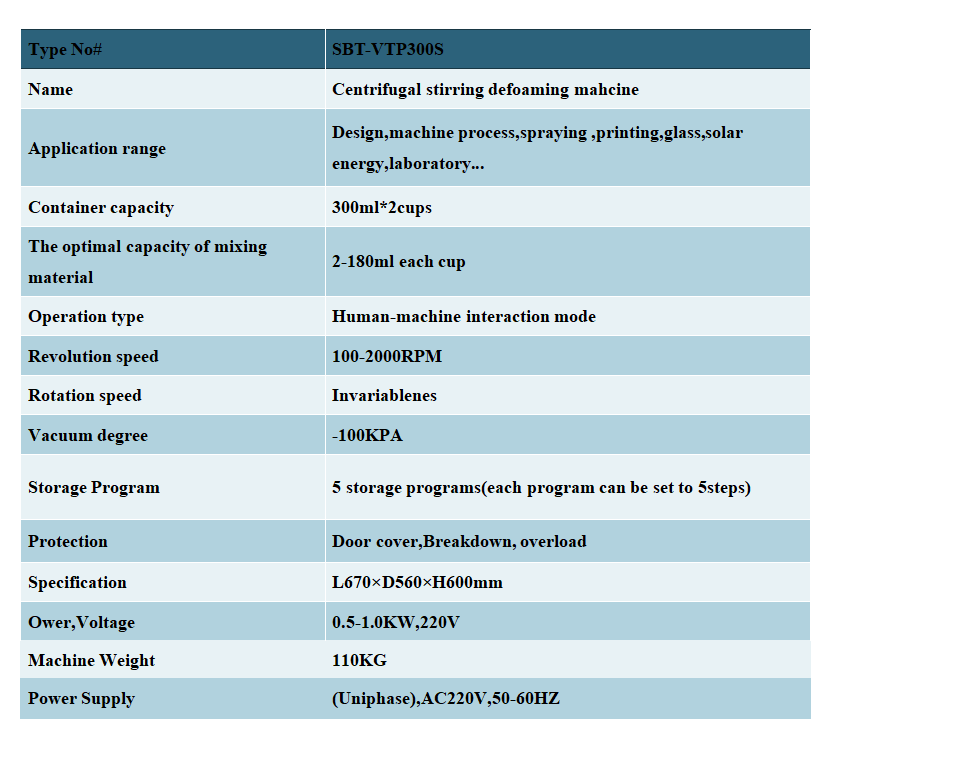

-Parameter