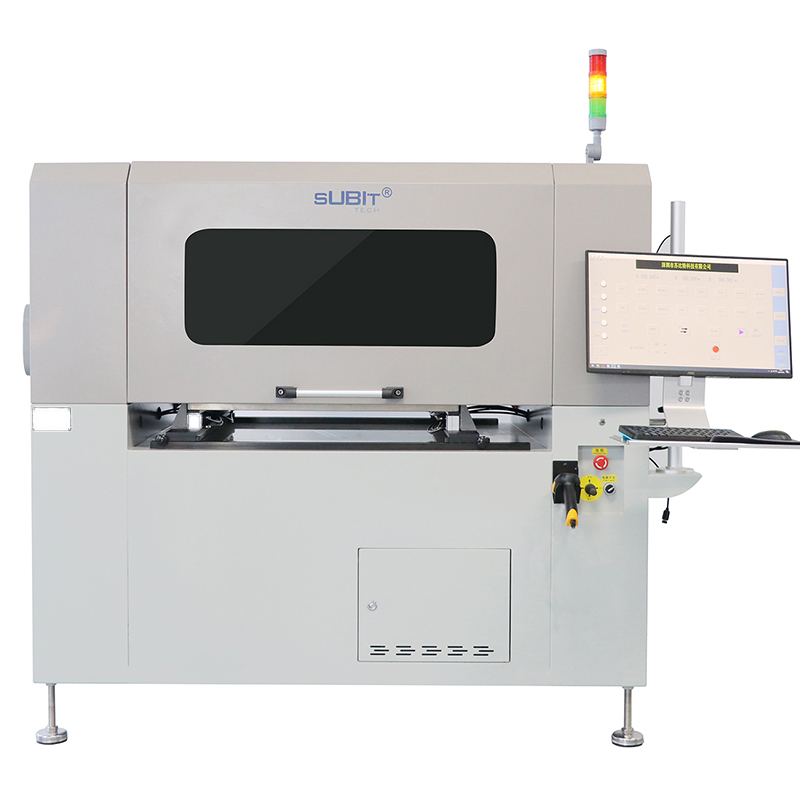

Automatic Stencil Inspection Machine

Automatic stencil inspection equipment is a high-precision inspection equipment dedicated for cleaned stencil after printing. The main purpose is to control the quality of cleaned stencil. Utilizes the automatic image measurement technology to scan the standard stencil image and collects parameters such as tension, and then compares it with the cleaned stencil to determines whether the cleaned stencil is qualified within the set error range. At the same time, it automatically records and uploads the stencil cleaning inspection results to optimize the quality of the stencil and realize the automatic management of the information chain.

This equipment makes up for the defects of low efficiency, poor quality, inability to manage and trace data, and inability to improve the process of manual inspection, and provides an important reference for the improvement and control of printing process.

Model Type:SBT-JC1009SA

The automatic stencil inspection machine is an optical measuring device that uses automatic image recognition technology to collect parameters such as stencil images and tension, and compares them with the error range and reference value set in the program to determine whether the cleaned stencil meets the requirements.

The traditional manual inspection method cannot guarantee the accuracy of the inspection, cannot accurately measure and compare, and has no data record

and analysis comparison. It is impossible to conduct accurate research on the impact of different stencil opening process treatments on quality during use;

Simple to operate and the inspection process is completed automatically, which not only greatly improves the inspection accuracy and speed, but also avoids human judgment factors, and provides direct and objective quantitative data for judging the quality of the stencil;

Mainly for the cleaned stencil after printed, measure and judge the correctness and rationality of the stencil, and monitor the quality of the stencil in use,

discover quality problems in advance, and prevent batch process problems caused by stencil quality;

Automatic tension test and image record, save test reports, and monitor steel mesh accuracy changes;

Improve automated control capabilities, timely prevent, discover, and control quality and efficiency problems caused by steel mesh problems;

Improve steel mesh opening process, solve printing machine problems, and improve SPI inspection pass rate;

Record inspection data in detail, generate inspection reports, improve process analysis links, and provide support for production process improvement;