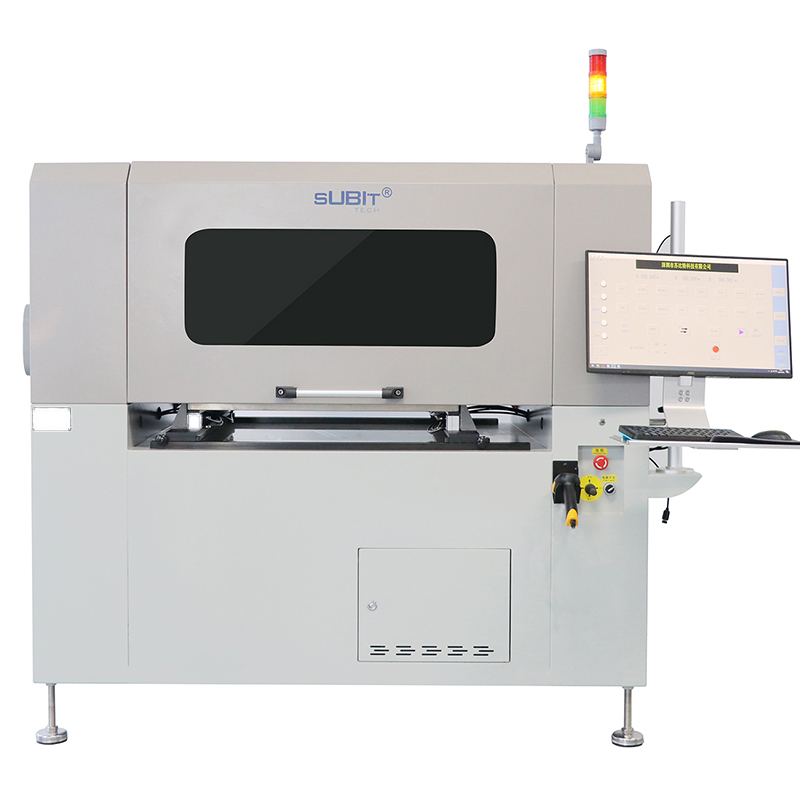

SMT First article detector

JD-FAI955 is an intelligent test terminal equipment,it solves some difficulties, such as the long time consuming of sample inspection, high human cost, incomplete test coverage, high probability of errors and difficulty to trace in the manufacturing process of the SMT production workshop.

It can detection the solder paste board (re-paste components after printed solder paste), pertinax (re-paste components after double sided adhesive), red rubber board (re-paste the components after printed red adhesive) and other types. Its inspection covers the wrong consumption of BOM, repetitive position, missing definition or more definitions of XY coordinates and other informative errors, more pastes, missing parts, incorrect parts, reverse rotation, rollover, and rotation of circuit boards. Besides, it also includes the electrical performance of resistance, capacitance, inductance and other elements (generally, it is the error of incoming materials).

The core hardware of JD-FAI955 includes the computer and LCR bridge, and they are perfectly combined through the self-developed software system, to realize the fast and accurate measurement of the resistance, capacitance and inductance.

Equipment Parameter

1 | Circuit board detection | SMT furnace front circuit board (solder paste board, pertinax and red rubber board) |

2 |

Detection method | Screen and inspect the blank position automatically. |

The resistance, capacitance and inductance can be measured using the LCR electric bridge. | ||

The diodes can distinguish polarity and light up LEDs | ||

The average detection speed us 3s/component. | ||

3 |

LCR electric bridge | Test frequency: 50Hz~100KHz |

R/Cmin. Measurement, R: 0.05Ω; C: 0.1pF | ||

Basic precision: 0.05% | ||

Measurement display range: R: 0.01m ohms - 99.9999M ohms L: 0.01nH~9999.9H C: 0.00001pF~9.9999F The test software can automatically control and select the measuring gear and parameters. | ||

5 |

Programming mode | Quickly import the BOM table and XY coordinates, and match with the bit map. |

It can extract the component specification from material description automatically. | ||

It supports the import of double-side coordinates and detection one side. | ||

Identify and label the blank position automatically. | ||

6 | Detection category covered | Data: wrong consumption of BOM, repetitive position, missing definition or more definitions of XY coordinates. |

Circuit board: more pastes, missing parts, wrong parts, reverse, flip over, offset or rotation, etc. | ||

SPC process control | Record the test data in the whole process, and output the statement in the format of Excel and PDF. | |

It can restore test scenarios in the later stage and provide the tracing basis. | ||

Server mode | The central data base is selected to realize the centralized and unified management of FAI data. | |

Inspection results display | 23.8'' liquid crystal display, OK/NG audible and visual prompts | |

Range of PCB size | No requirement | |

PCB clear height | No requirement | |

Voltage and power: | AC220V 50/60Hz, less than 1.5KVA | |

Equipment weight | About 180KG | |

Outline dimension | 1160mm x 800mm x 1100mm (W*D*H) |